Basics and Types of Encoders

In sensors, as the name suggests, an encoder is a device that reads codes in a specific format.

Encoders are used to measure precise displacement in rotational and linear motion and are widely applied in any field utilizing closed-loop control. It can be said that wherever controllable motion exists, encoders are likely to be found.

Encoder Basics

Unlike the encoding storage method in computers, where 0s and 1s are stored on chips or disks at any physical location on the medium and data can be overwritten, encoders require a strict one-to-one correspondence between the code and the physical position. The encoding medium can be glass, metal, magnets, etc., and once produced, it cannot be modified.

The following image shows the moving part’s code pattern used in optical encoders:

The measurement process of an encoder mainly involves two parts: the moving part and the stationary part. In all encoders, position information is stored on the moving part in various ways. Different storage methods, combined with different reading mechanisms, result in variations in performance and cost.

Classified by principle

- Based on different principles, the main types are:

- Optical encoder: Uses transparent and opaque lines on the moving part to represent codes and determine position.

- Capacitive, inductive, and resolver encoders: Measure position through electromagnetic interaction between specially designed circuits on the moving and stationary parts.

- Magnetic encoder: Uses specially magnetized N and S poles on a magnet in patterned form, and determines position by reading the magnetic field strength.

Among the three main technologies above, optical encoders offer the highest accuracy due to their one-to-one correspondence. Capacitive, inductive, and magnetic encoders are based on electromagnetic principles and are generally less accurate, but they offer advantages that optical encoders cannot achieve.

Classified by output

- Mainly divided into the following types based on output:

- Absolute encoder:

- Single-turn absolute encoder: detects absolute angle within 360˚

- Multi-turn absolute encoder: detects absolute angle within 360˚ and tracks the number of revolutions

-

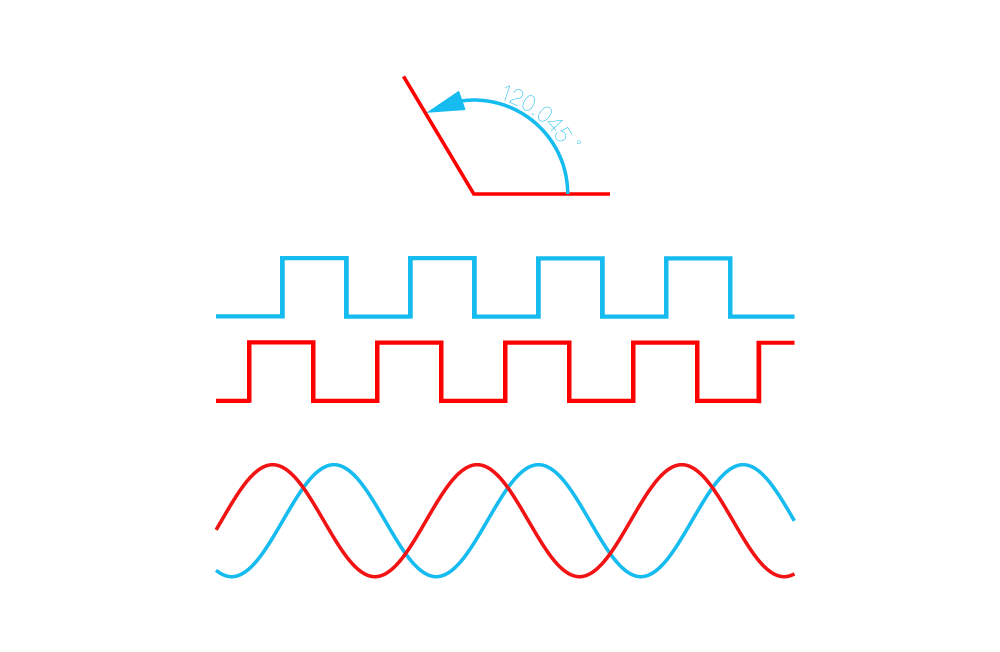

Incremental encoder:

- Square wave incremental encoder: outputs square waves with a 90˚ phase difference

- Sine wave incremental encoder: outputs sine waves with a 90˚ phase difference

Absolute encoders output digital signals with specific data formats, requiring communication devices on the host controller.

Incremental encoders output analog signals. Square wave incremental encoders represent position through square wave state changes, while sine wave incremental encoders use sine wave analog signals. The controller obtains position by ADC conversion.