Encoder Mounting and Installation

《Encoder Accuracy》In this article, it is pointed out that the installation and fixation of the encoder directly affect the accuracy of the measured angle. To achieve high-precision angle output, King Kong Technology’s patented technology offers a unique mounting and fixation solution. This article will primarily introduce this solution.

Mounting and Accuracy

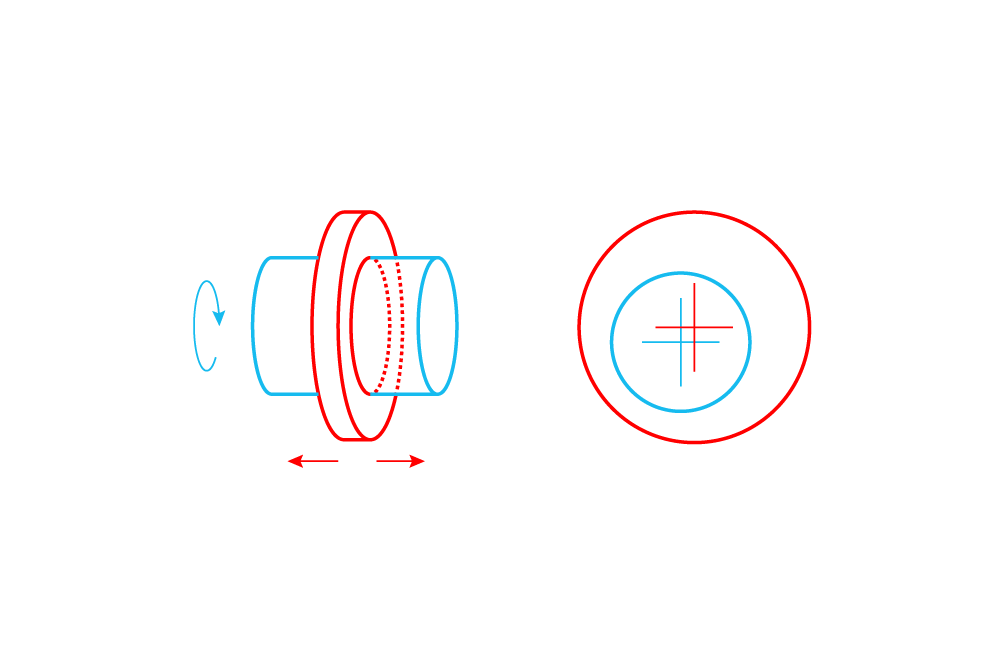

A split-type encoder consists of two parts: a moving part and a stationary part. These two parts are respectively fixed onto the moving component (shaft) and the stationary component (housing) of the measured device. Once fixed, the relative position between the moving and stationary parts of the encoder is established. Poor relative positioning will directly affect the accuracy of the encoder’s data.

For split-type encoders, a common approach is to fix the components directly onto a PCB. However, this method introduces the following drawbacks:

- Variations in mounting errors lead to poor consistency in accuracy.

- Shifting may occur under vibration.

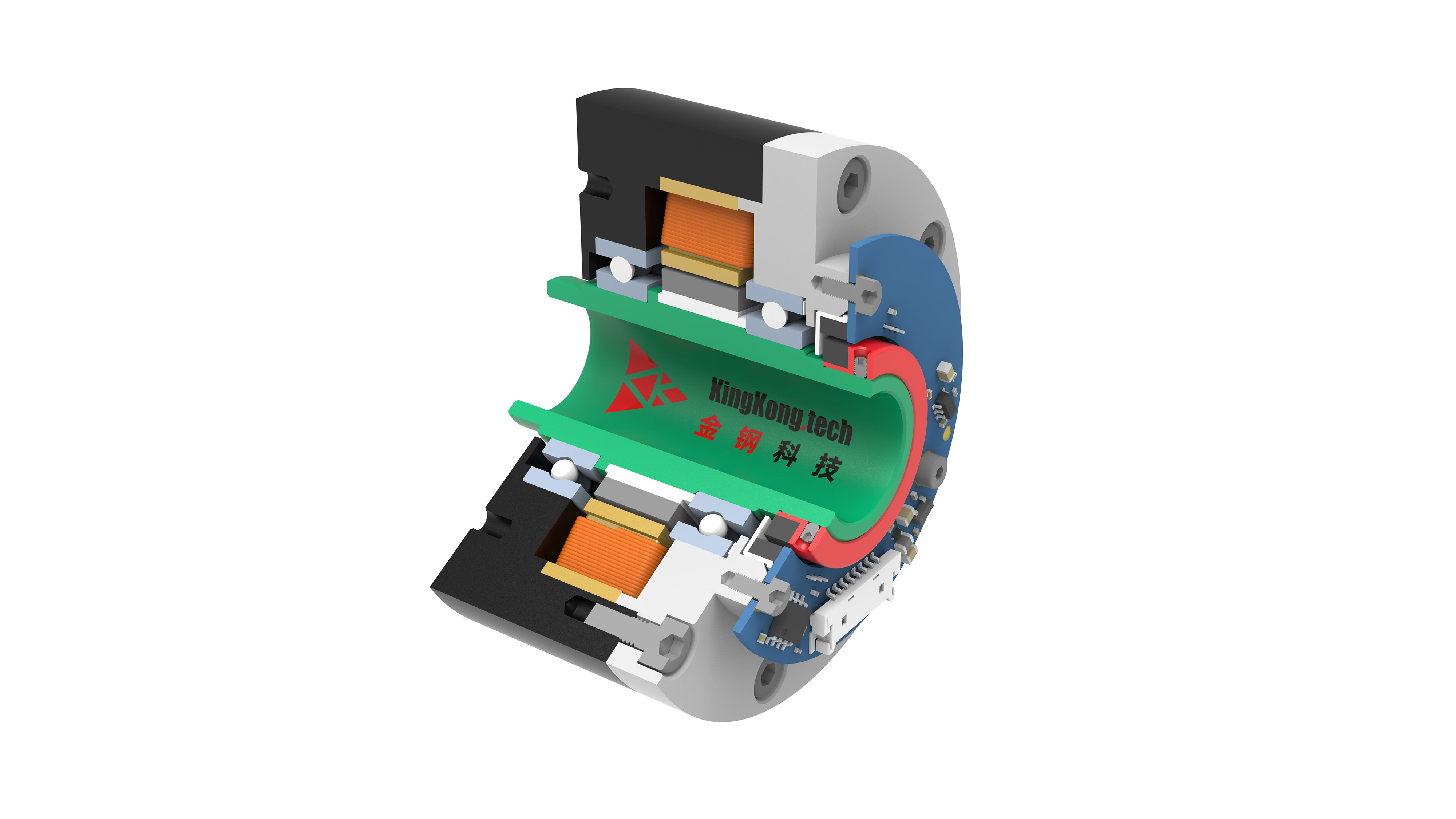

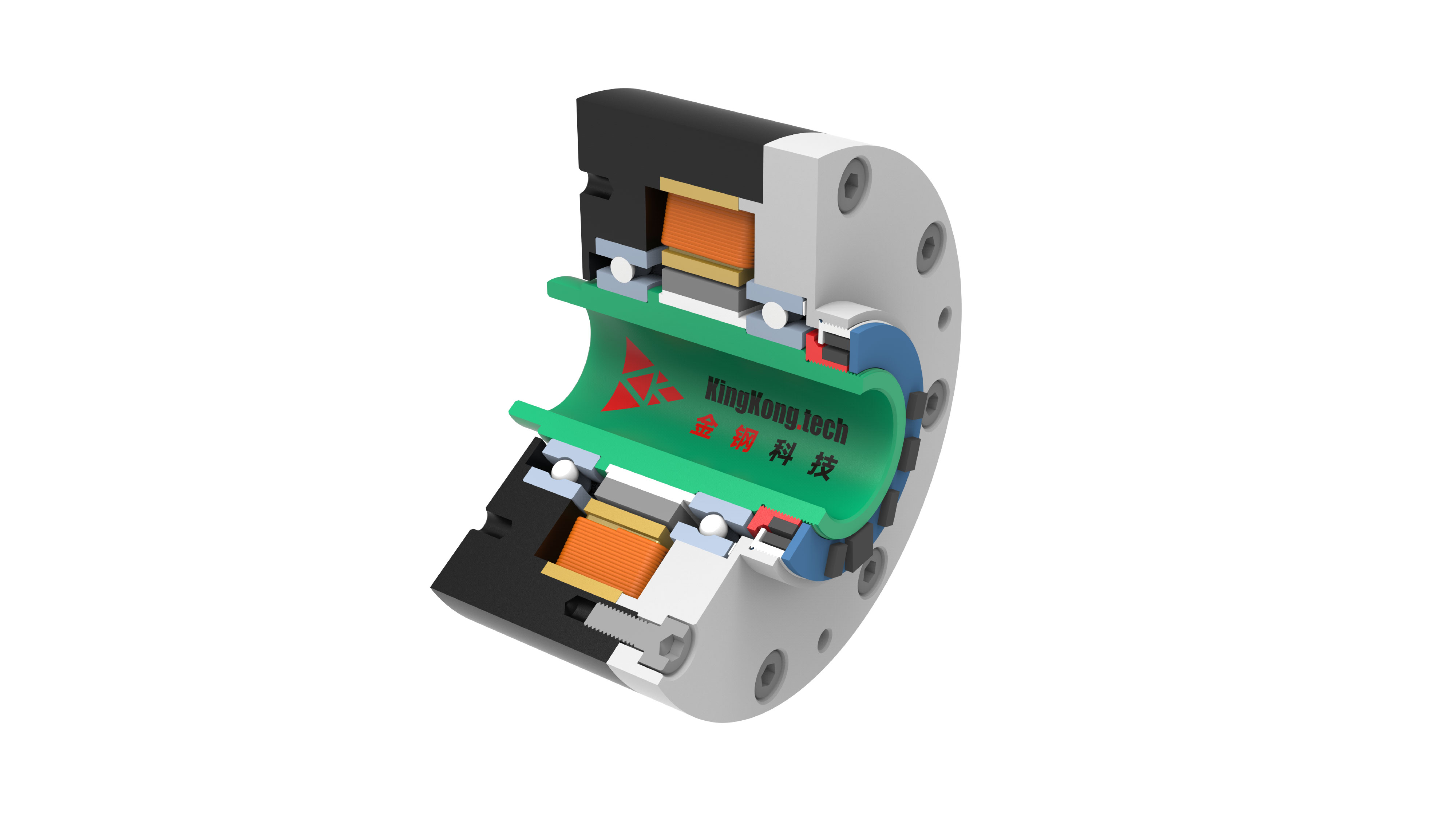

Hollow Shaft Magnetically Shielded Encoder

KingKong Technology’s magnetically shielded hollow encoder design achieves the following:

- Hollow Structure:Can be mounted on the shaft or shaft end, with no positional constraints.

- Magnetic Interference Shielding:Provides a clean environment for magnetic fields and measurement, and can even be installed in close proximity to the motor coils.

- Mating Installation:It enables concentric installation of the encoder’s stationary part with the housing, achieving optimal fitting accuracy with the encoder’s moving part.

All King Kong Technology magnetic encoders undergo one-to-one factory calibration. To address consistency errors in magnetic processing, each magnetic encoder contains unique calibration data corresponding to its specific magnetic ring. Using mechanical components for fitting installation can greatly restore the relative position of the encoder’s moving and stationary parts as during calibration. After user installation, this ensures the highest data accuracy.

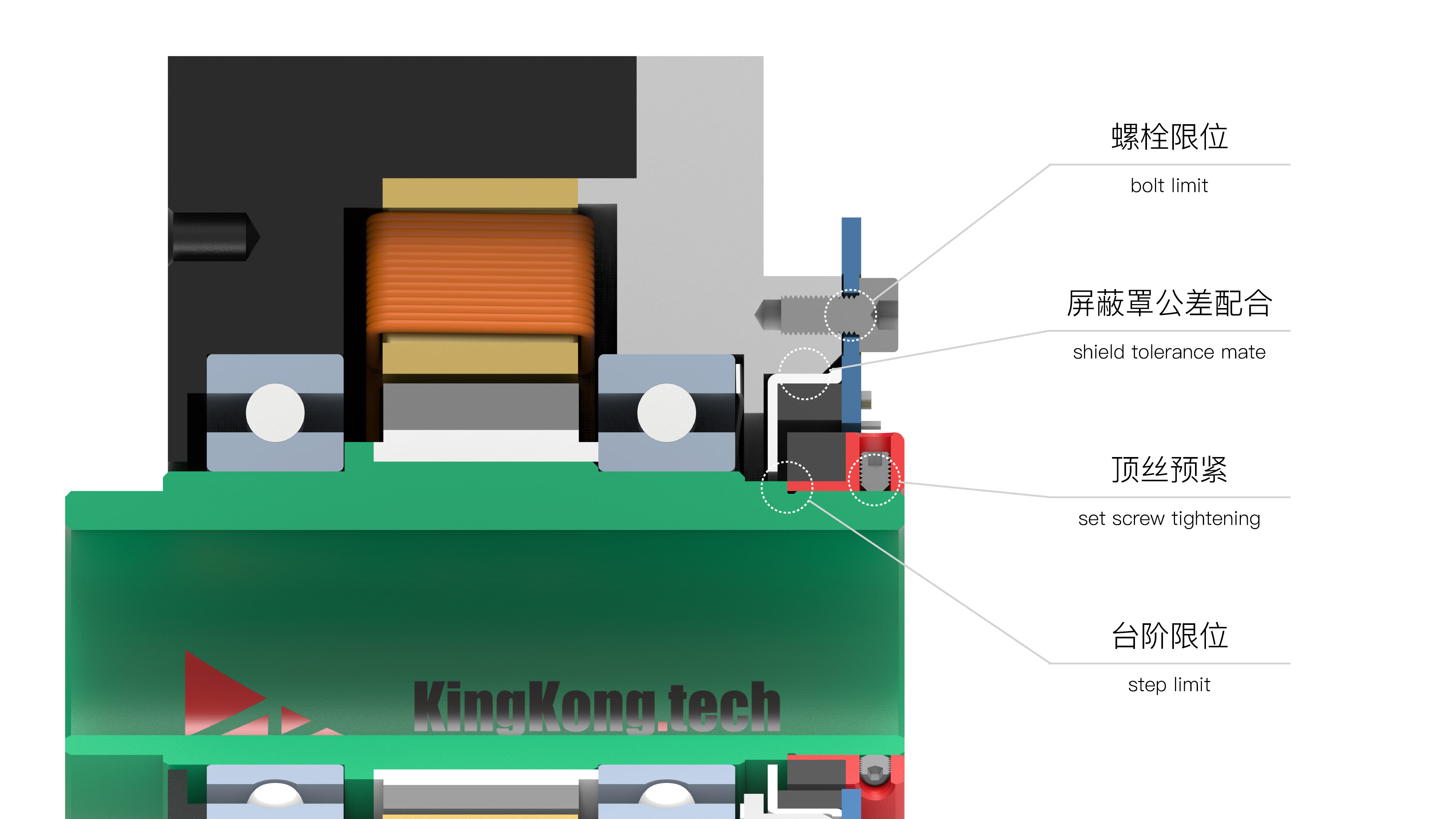

Standard Model Fitting Installation

The standard model features a shielded cover structure. The encoder body is fixed using mounting holes on the PCB, while the magnetic ring is preloaded and fixed with set screws. The installation sequence is: first install the encoder body, then install the magnetic ring.

Encoder Body:The encoder’s shielded cover fits precisely with the motor housing, ensuring centered alignment and minimizing concentricity errors with the shaft and magnetic ring.

Magnetic Ring:The shaft shoulder is used for positioning, ensuring the axial relative position between the magnetic ring and the encoder body matches that during calibration.

Once installed, the relative positions closely match factory calibration, minimizing positional errors and ensuring maximum accuracy.

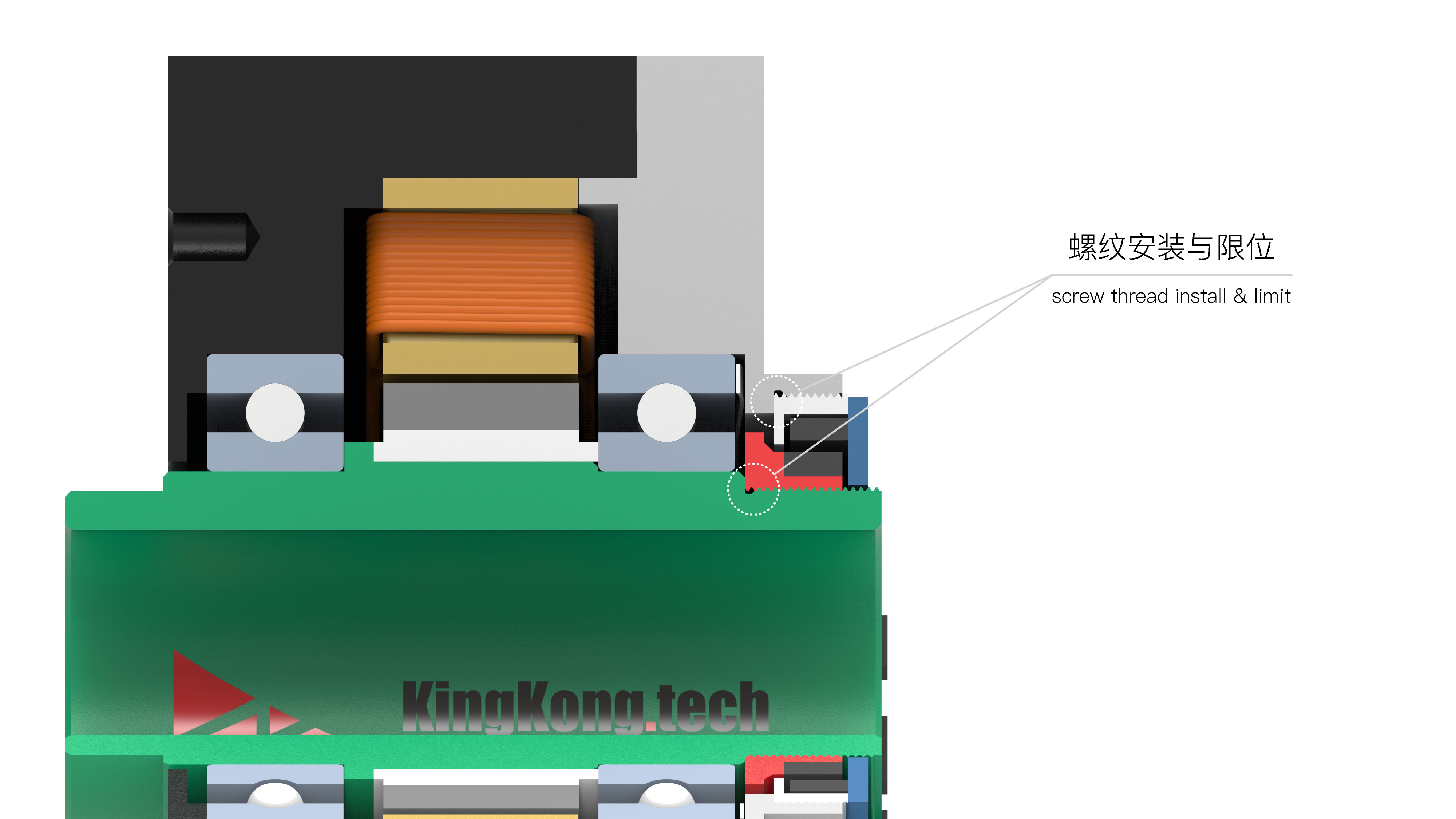

Compact Model Fitting Installation

The compact model is designed to maximize space utilization,The ring width can be as small as 6 mmBoth the encoder body and the magnetic ring are fixed using fine-thread screws, with the mounting sequence being: first mount the magnetic ring, then mount the encoder body.

Magnetic Ring:Fine-thread mounting on the shaft with shaft shoulder positioning ensures concentricity, preload, and restores the axial position as calibrated.

Encoder Body:Mounted to the housing with fine-thread screws, this connection ensures concentricity and preload, aligning the encoder body with the housing center to minimize concentricity errors with the shaft and the magnetic ring on the shaft.

Both use threaded mounting with positioning. Fine threads minimize space usage while ensuring precise calibration reproduction for the highest angle accuracy.

Advantages of the Compact Model

Using a compact fitting installation for the hollow encoder enables unprecedented space-saving inside the motor, freeing up more room for other components (such as driver circuits). This optimizes the joint shape to achieve the best overall size while providing strong accuracy assurance.