Principle of Patterned Magnetic Encoders

Magnetic encoder technology has long been regarded as one of the most reliable and advanced principles in encoder industrialization. Compared with optical encoders, it provides superior environmental resistance and cost efficiency, making it essential in servo systems.

Mission

As a leading company in magnetic encoders, KingKong Technology sees growing demand for compact, precise, and cost-effective solutions as smart devices—especially robots—continue to shrink in size. These trends place higher requirements on servo systems and their encoders.A strong demand forcompact and precise solutions.

In response, KingKong Technology has carried out substantial foundational R&D, such as:

- Magnetic field algorithm design

- Magnetic materials

- Magnetic structure

- Magnetic process

- Magnetic analysis algorithm

- Magnetic environment adaptability

- Systematic fundamental exploration......

With years of experience in the robotics industry, KingKong Technology understands customers’ key challenges and needs. As demand for smaller, more precise devices grows, we continuously improve fundamentals—principles, materials, structures, processes, and algorithms. Our strong magnetic R&D drives solutions that instantly impress. The patterned magnetic encoder is one such product.

Patterned Magnetic Encoder

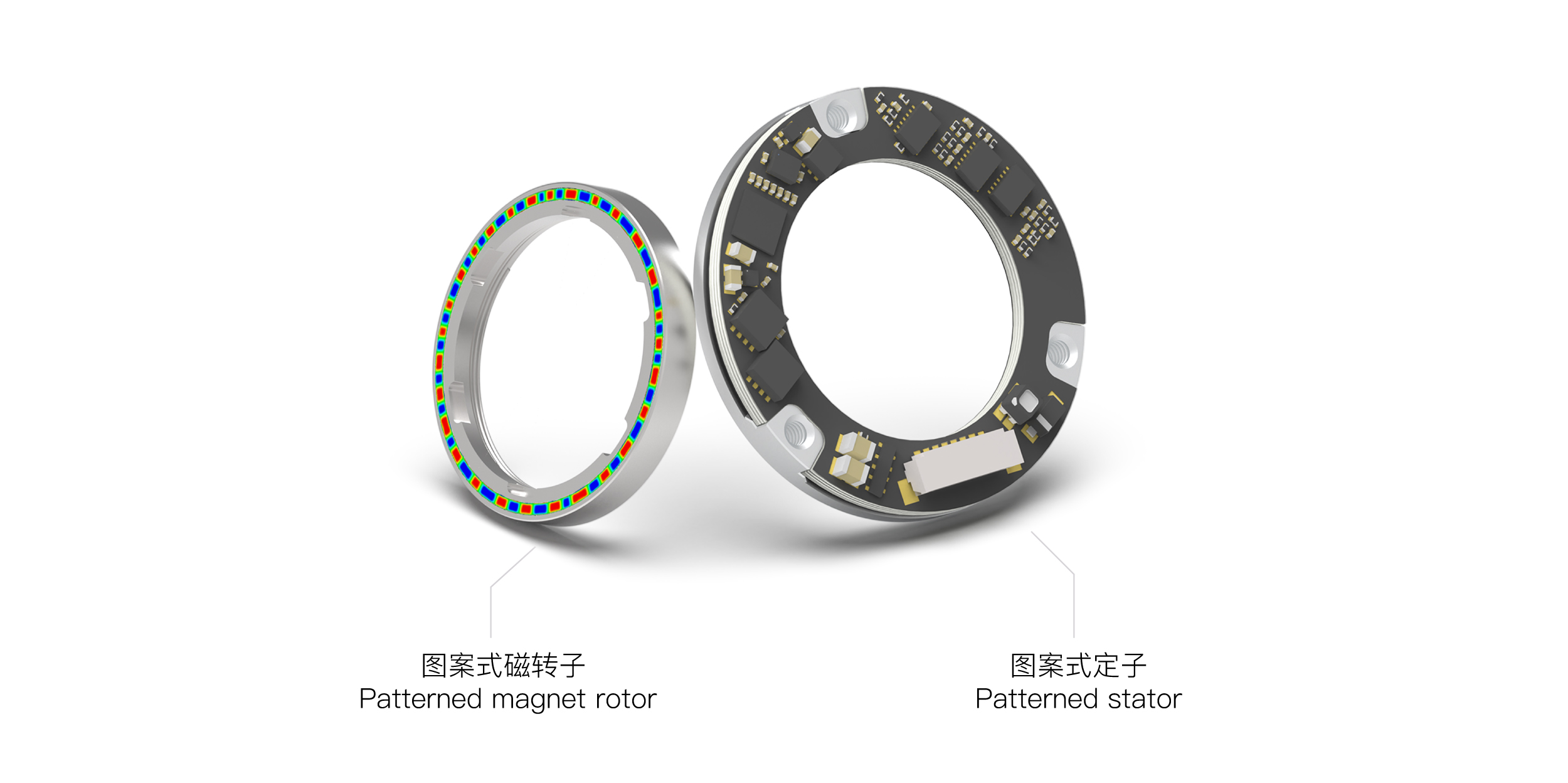

The encoder consists of two parts:

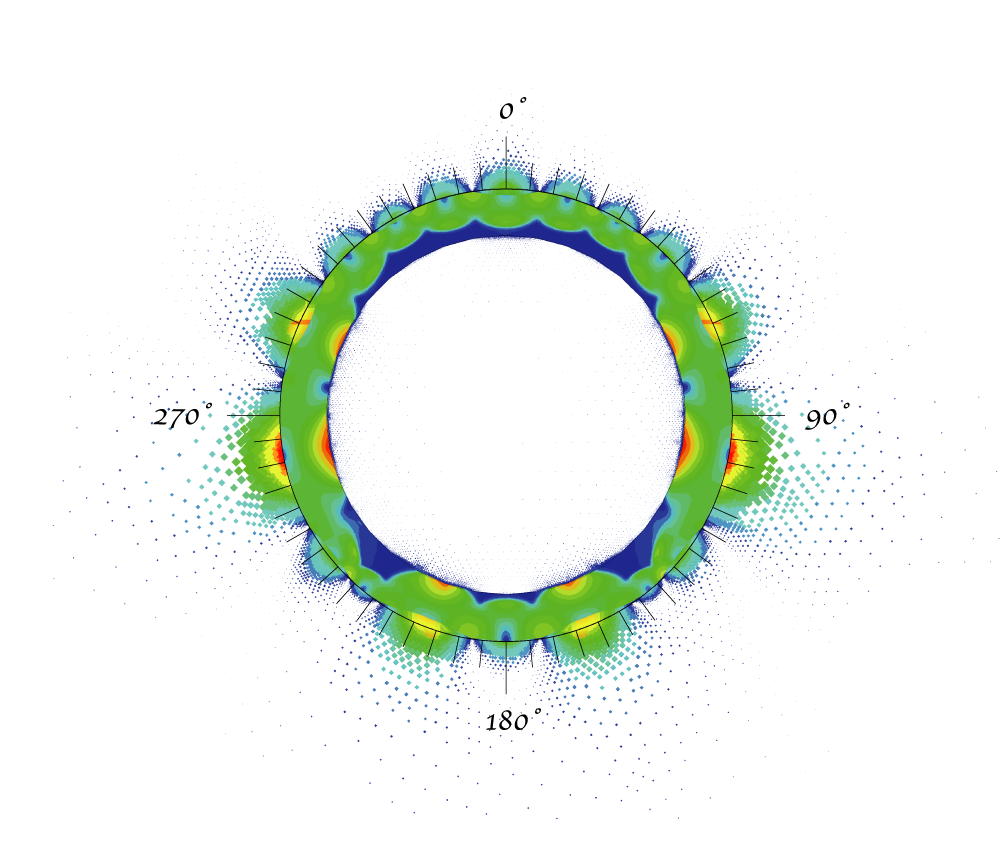

- Patterned Magnetic Rotor: The rotor uses a pattern-based principle similar to optical code discs. As shown in the image above, the magnetic field distribution is uneven and features a full series, allowing one full rotation to be divided into coarse fractions comparable to optical levels, achieving high-precision measurement.

- Patterned Stator:The stator uses a measurement scheme matched to the patterned magnetic rotor, enabling angle detection and precise, synchronized output even at extremely small sizes.

The measurement principle is shown in the video:

This product can achieve:

- Ultra-high accuracy: It approaches the same size as optical encoders and matches their coarse resolution at the same dimensions (the more coarse divisions, the higher the achievable accuracy).

- Ultra-compact size: The encoder's radial width (outer radius minus inner radius) is only 5 mm, and even the dual encoder version is just 7 mm per side—enabling simultaneous measurement of two axes.

- Exceptional resistance to environmental interference: Oil, dust, and electromagnetic interference have no effect on measurement, making it ideal for open environments.

Thanks to KingKong Technology’s efforts, the accuracy of magnetic encoders with the same code disc size now closely approaches that of optical encoders—while retaining the many advantages of magnetic technology.At the same time, we have achieved the following with this product:The world's most compact form factorIt makes designing precision and smart devices easier than ever—no more worrying about encoder size or layout. Its footprint is so small, it’s almost invisible.

Based on this principle, the DPT dual encoder series enables measurement of two axes within just 7 mm of radial space. It makes a significant contribution to the miniaturization of integrated robotic joints—helping robots become smaller and more precise.

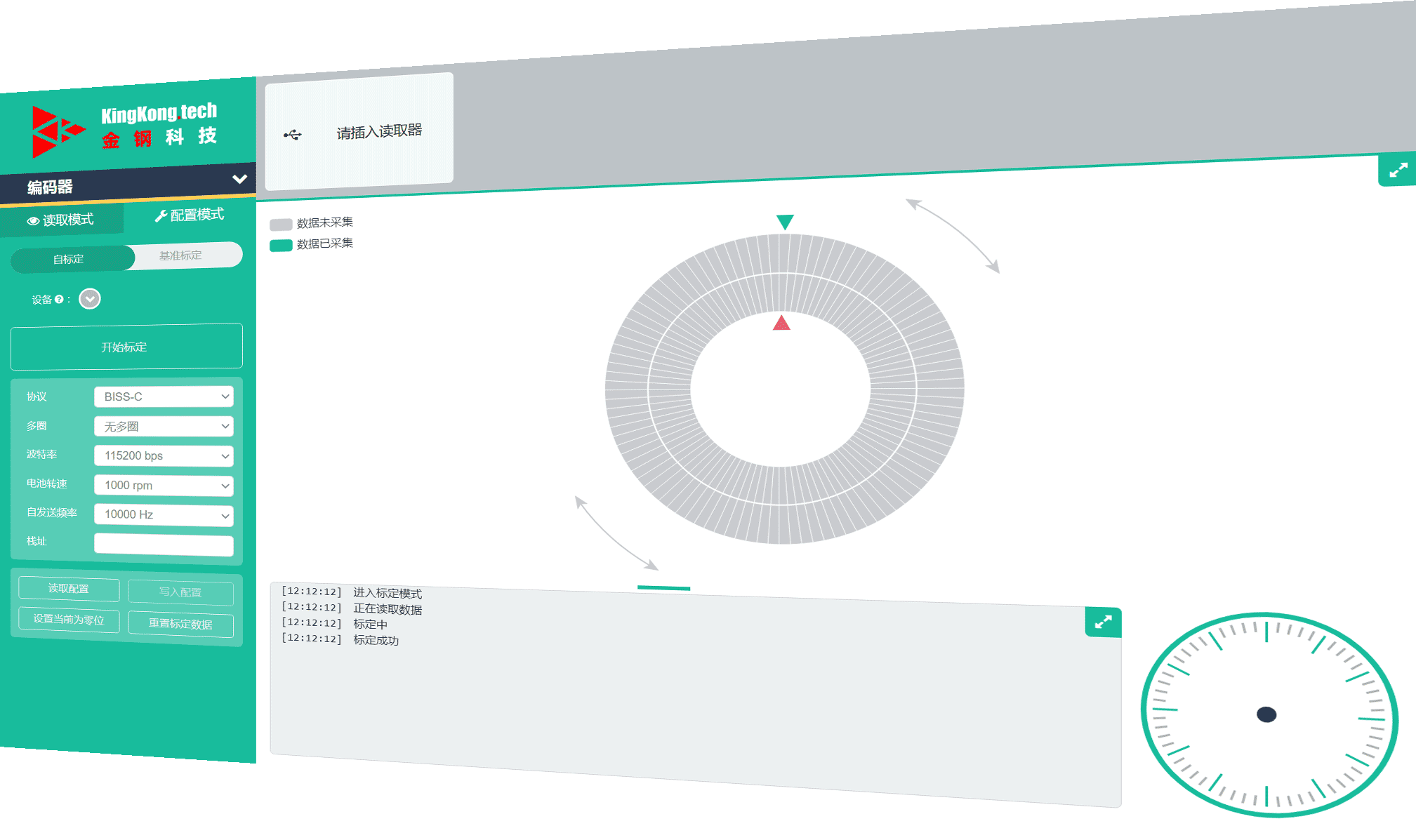

Recalibration process

KingKong Technology’s patterned magnetic encoders are calibrated and aligned before leaving the factory. However, after installation in the final product, various mounting misalignments may affect measurement accuracy. To address this, KingKong Technology provides a recalibration process to help customers easily achieve optimal measurement precision in actual use.

After mounting, the customer connects the reading device to the encoder and plugs it into the computer’s USB port. They then open the software and start the recalibration process. By manually rotating or using sensorless drive to turn the motor, the encoder’s rotor completes one full rotation while the encoder’s stator collects the current data. KingKong Technology’s unique spatial recognition calibration algorithm identifies the current installation errors, including:

- Radial error

- Axial error

- Tilt error

KingKong Technology’s unique spatial error identification technology It can even accurately measure the current spatial errors, then further calculate and compensate the angular errors, rewriting the corrections into the encoder. This maximizes the encoder’s measurement accuracy and output performance. if the structural components have certain manufacturing or assembly errors, this process can identify and compensate for the mechanical errors.

Below is the interface of KingKong Technology’s recalibration software: